PZYZC News

Customers from the Middle East Visited PSYZC Bearing Factory

release time:2019/4/26 16:25:05

On April 22, 2019, customers from the Middle East visited our factory. This customer is a large bearing solution developer integrating R&D and development in the Middle East, with more than 25 years of experience, 3 branches, and several sales teams. They visited the semi-automatic production workshop and automatic bearing production line, bearing precision testing room, and assembly & finished product testing workshop. And they are very satisfied with the factory service and product quality. Finally reached an agreement to sign the order contract.

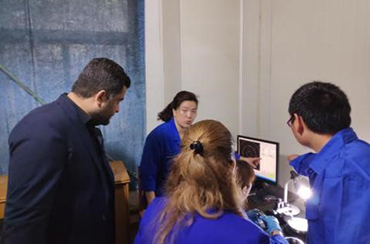

The customer has strictly tested for a series of parameters of bearing accuracy. Include: dimensional accuracy, rotation accuracy, bearing clearance dimensional accuracy, and rotational flexibility and vibration noise of the finished bearing. They randomly select any bearing component for testing at any inspection stage, and the test results meet standard.

Welcome customers to the factory.

We have a short meeting in the office, our sales manager Mr. Peter introduce our company's development history.

Tests in the bearing precision test room. Attached below pic is the round gauge, which enlarges the roundness of the bearing by 4000 times and images it on a computer to compare it with the standard circle to check if it meets.

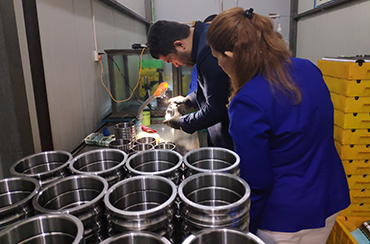

Standard parts warehouse. We use standard parts to check the inner and outer dimensions of the bearing components on the production line, and whether the thickness is up to standard.

Visiting the fully automatic production line, they are introduced in Germany can maintain the working environment temperature at 25℃. The automatic bearing ring production line is imported from Germany and is the best choice for automatic machining and large-scale mass production of high-precision bearing rings.

Bearing assembly & testing workshop. All bearing rings are cleaned on the washing machine before entering the assembly shop, then cleaned with petrol and classified after short-term rust.

In the assembly shop, we will do: angular contact ball bearing thermal assembly, bearing demagnetization, finished bearing cleaning (100% with 120# gasoline for more than 2 minutes), and bearing grease filling prevention.